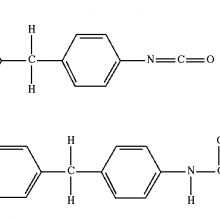

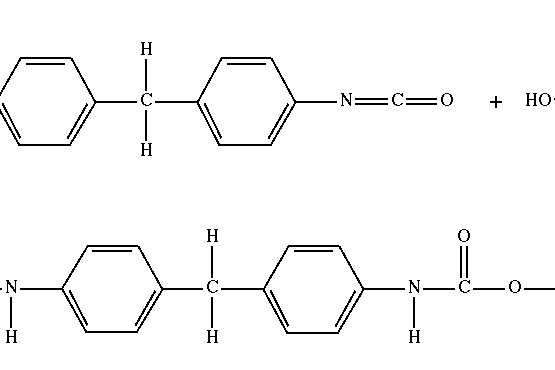

Polyurethane polyurethanes were first discovered by Otto Bayer in Germany in 1937, and since then these materials with their special properties have greatly advanced in various industries around the world.

Iranian Petrochemical Polymer Company, supplier of polymer raw materials

About Us

Iranian Petrochemical Company

Iranian Petrochemical international Trading Company was established since 2012 with the aim of supply, export and transportation of petrochemical products in domestic and foreign markets.

Iranian Petrochemical Company with years of brilliant experience and specialized staff is ready for any cooperation with international companies to offer the best materials and provide the best consultation about Iranian petrochemical raw materials.

Products

Polyethylene is a type of thermoplastic polymer, which means that this material becomes liquid when it reaches its melting point and solid when it reaches the freezing point.

Chemically, polystyrene is a long-chain hydrocarbon in which the variable carbon centers are attached to phenyl groups (the name given to ring benzene).

Polycarbonate polymer belongs to the family of thermoplastic polymers. Polycarbonate is the hardest transparent material that is used as a suitable alternative to glass in various parts of the building.

Polyethylene terephthalate (PET) is a thermoplastic polymer from the polyester family that is produced by stepwise polymerization by the reaction between pure terephthalic acid (PTA) and monoethylene glycol (MEG).

It can be said that at present, it is one of the most valuable products of the petrochemical industry, which annually produces about 45 million tons in the world and is the third most widely used polymer in the world after polyethylene and polypropylene.

Polypropylene or POLYPROPYLENE with the chemical formula -n [CH2-CH (CH3)] – is a versatile material that incorporates properties such as lightness, strength, high heat resistance, stiffness and flexibility and stability.

ABS is a terpolymer made by polymerization of styrene and acrylonitrile in the presence of polybutadiene and has an amorphous structure. The proportion of this formula can vary between 15 to 35% acrylonitrile, 5 to 30% butadiene and 40 to 60% styrene.